The History of Bread

page 4

The Romans enjoyed several kinds of bread,

The stone-age man's method of pounding wheat between two stones

was not basically very different from the, method of grinding by

millstones in a wind or watermill. In either case the bottom stone

was fixed, and a grinding movement by the top stone was the required

action to produce ground meal. The stones were round, the bottom one

fixed, and the top stone, or runner, was balanced on a spindle which

could be raised or lowered, making the space between it and the

bottom stone as narrow or as wide as the miller wanted. Both stones

were corrugated, so that when the top stone was running, the wheat

between it and the bed was scraped rather than bruised. The wheat to

be ground entered the mill by a hole in the top stone, and was

carried out towards the edge, leaving in the form of a meal by holes

round the outside of the bed. By raising or lowering the top stone,

the meal could be made as fine or as coarse as required.

To obtain white flour from this meal, it was sifted through sieves

of different mesh; the finest sieve made of very strong silk.

Nowadays in America stone mills are of course not used much for flour-

making; only a few are still used for wholemeal flour and specialty

millers.

|

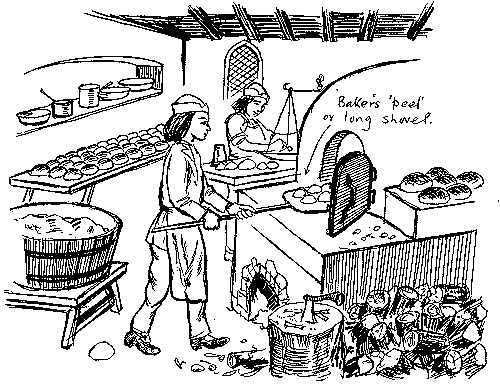

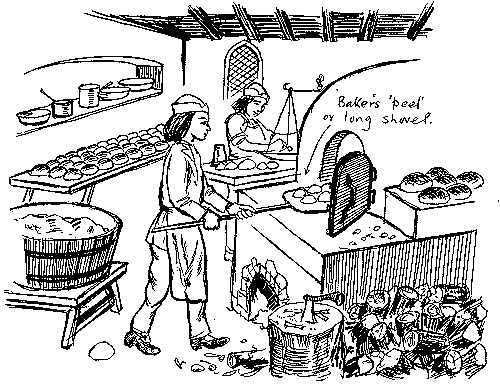

An old English Bakery

An old English Bakery |

Watermills for grinding flour were of two varieties; in the first

kind the wheel turned horizontally in the stream, its shaft turning

the millstone directly, without any gears. The second type had its

wheel standing upright and the shaft at right angles to the stones,

moving them by means of a system of cogs.

The windmill made its appearance at the end of the twelfth century;

as it depended for its working on the amount of wind available, it

was not by any means an efficient machine. For over 700 years these

attractive buildings with their long sails were used for grinding

corn for people and for cattle-feed. There are still one or two of

them preserved in various parts of our country.

The plant of a modern flour mill has four main functions which are to

store a reserve of wheat, to remove all the impurities from the wheat

and prepare it for milling, to mill the wheat and separate flour from

the bran and skins of the wheat, and to store the milled products

before shipping.

You have no doubt seen the wheat stores or silos at a flourmill.

They are tall buildings housing a number of large cylindrical bins.

They are 60 to 90 feet high and may each hold 1,000 tons of grain.

The silo is equipped with mechanical elevators for dealing with

wheat, which invariably arrives, by road to the mill. It is also

equipped to weigh the wheat, to clean it of impurities, dry it to a

safe moisture-content before storage.

|

| The cleaning section or screen room draws wheat from the silo. Here

wheat is first cleaned on sieves, which removes all the impurities

different in size from the wheat grain. Magnets next remove any

fragments of iron or steel. Further equipment then takes out

impurities similar in size but different in shape from the wheat

grain, such as foreign cereals or round seeds. In the mill, the grain

passes through more than forty processes before it emerges as flour

and bran.

At the first stage of the milling process, the clean blended wheat

passes between chilled iron rolls, which revolve rapidly, one roll

faster than the other. These first sets of rolls (known as the break

rolls) have ridges or "flutes" on them. The slower moving roll tends

to hold the wheat while the faster one strikes the grain as it passes

between them. They are set very delicately, so that as the wheat

passes between them, they do not crush it, but shear it open in order

to make the inner white floury portions of the wheat come away from

their brown outer skins. If the wheat were merely crushed, the brown

skins would break up into countless tiny fragments, and would mix

with the white portions so thoroughly, and so finely, that they could

never be separated properly. These skins would then discolor the

flour badly and also spoil its baking qualities.

Some of the white floury portions will have broken away cleanly from their brown outer skins, but other white portions will still have pieces of skin fastened firmly to them. Therefore the materials from the break rolls must be sorted out. The pieces of brown skin must be separated from the white portions, and some of the material must be sent back to the fluted rolls for further separation. Mainly sifting the mixture does this sorting out of particles from the 'break' rolls; elevators first move the mixture to the top of the mill. There are several different types of sieving machine but usually only two kinds are used at this stage: first the 'plansifter' and then the 'purifier'. This is how they work. |

|

Rollers used to grind the flour kernels

|

wheat after the first run through the rollers wheat after the first run through the rollers

http://www.oznet.ksu.edu/aawf/July/july_5.htm |

|

Plansifters on Sifter Floor The plansifter is an arrangement of

about a dozen large sieves, one below the other-just like the floors

of a tall building. The top sieve has the coarsest mesh, the next not

quite so coarse, and so on. These sieves are all made to swing

briskly by machinery. The broken wheat comes first onto the top

sieve, and then through the others in turn, each sieves helping to

separate the material. The first sieves remove the bran skins, which,

because they still have flour particles adhering to them, are

returned to another milling machine for re-treatment. The finest

sieves are of silk, and these separate flour, which then starts on

its way to the flour-packing spout. The majority of particles are not

of bran, of course, but are at present too large for grinding down

into flour. They are known as semolina at this stage. They are taken

to the next sieving machines - the purifier.

The purifier is an ingenious machine that not only separates the

broken parts of the wheat by sieving, that is, according to size, but

it also separates those parts which are of the same size but of

|

| different weight. Using currents of air does this. The skins are much

lighter in weight than the inner white floury parts, and a current of

air is drawn upwards through the mixture on the sieve, lifting up

and 'floating' the skins, but allowing the heavier white parts to

remain on the sieve and be separated by the sieving motion. Sieving

on the plansifters and purifiers will eventually have removed most of

the brown skins. Now the inner floury portions of the broken wheat

grains are brought together for final milling between the 'reduction'

rolls.

These are smooth rolls that mill down very gradually and

accurately the inner white portions of the wheat (the endosperm or

semolina) into smooth, powdery, 'lively' flour. Thus flour, clean

bran and wheat feed are collected, each in its own channel, from a

large number of different machines and are finally brought either to

bulk storage bins or to a packing floor where they are filled into

sacks and weighed. Lastly, the packed products are sent to the mill warehouse and stacked ready for shipment. However, around 70% of the flour is shipped in bulk. The whole process of cleaning, and milling, etc., is

done by machine, with the material passing automatically from machine

to machine, and from one stage to the next. No hand touches the wheat

from the moment it arrives, throughout its long journey in the mill,

until the flour leaves the mill for the baker, biscuit-maker and

other users.

|

Today the range of flours available is wider than ever before. Each

type of flour has been milled with specific uses in mind. Flours

vary in their composition and, broadly speaking, are defined by their

rate of extraction. This refers to the percentage of whole cleaned

wheat grain that is present in the flour. The three basic flour

categories are Wholemeal -100 percent extraction, made from the whole

grain wheat with nothing added or taken away. Brown -usually contains

about 85 per cent of the original grain; some bran and germ have been

removed. This flour is frequently labeled as "85 per cent flour"

rather than brown. White -usually 75 per cent of the wheatgrain. Most of the bran and wheatgerm have been removed during milling.

Other varieties of flour:Wheatgerm -white or brown flour with at least 10% added wheatgerm. Malted wheatgrain -brown or wholemeal flour with added malted grains. Stoneground -wholemeal flour ground in traditional way between two stones. Organic -flour milled from wheat grown and processed naturally without the use of chemicals.

Bread in this country has to everybody's benefit reached a high

standard of purity and hygiene. Bread is perhaps the most important

item in our diet; it has often been called the staff of life. To give

you an idea of the benefit we get from flour and bread, a Government

survey showed that flour and bread provided us with more energy

value, more protein, more iron, more nicotinic acid and more vitamin

B1 than any other basic food. Bread comes to us in many interesting

shapes and Flavors, from the time-honored 'cottage' loaf, to some of the

delicious Vienna rolls. Nowadays, the sliced and wrapped loaf is the

most popular loaf of all. It is ideal for making sandwiches for

picnics, and for workers' lunches; there is, however, an important

drawback. If you like your bread with a beautiful rich golden crust

on it, do not buy the ready-wrapped variety.

One of the nicest things in life is to come home hungry from school or work, and have set before one the fresh, buttered crust from a well done home made loaf.

|

Page 1 Page 2 Page 3

Links

Kansas State University Research and Extension

Freshloaf an Old Fashioned Bakery

The Story behind a loaf of Bread

Minnesota Historical Society

|

|

|

wheat after the first run through the rollers

wheat after the first run through the rollers